Test probes

Modular test probe system allows quick changeover between armature and stator testing on the same tester.

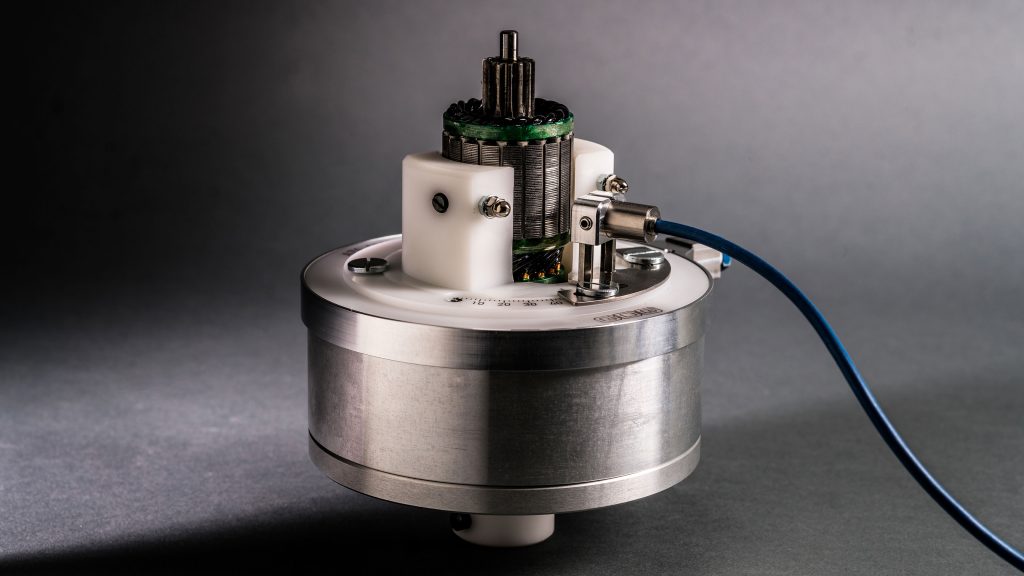

Adaptation of armature with barrel collector

Pneumatic contacting

Contacting with two contacts per collector bar

Infrared measurement for temperature compensation

Interchangeable parts for different core and shaft diameters

Adaptation of armature with flat collector

Face side contacting

Option: Radial contacting for armatures with carbon commutator

Infrared measurement for temperature compensation

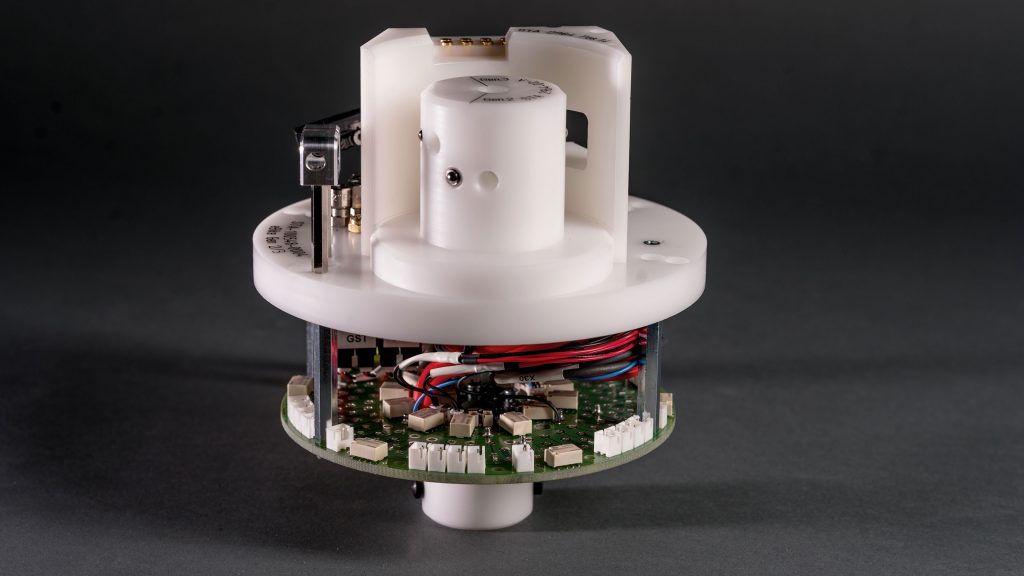

Test probe for stators with hot staking test

Direct contacting

Contacting of the wires by pneumatic knife contacts

Interior view of a stator test probe

Adaptive wiring

The test probe electronics allow customer-specific adaptations and extensions of the test functionality